Introduction

This is a guide on the technique on how to terminate wires for a Garmin Avionics Install.

This is not approved material and all work done on aircraft should be done by certificated individuals per the appropriate manual.

This guide covers the use of a twisted pair wire but the technique is applicable to any shielded wire.

-

-

DMC crimpers with appropriate turret

-

Wire strippers

-

Flush cuts

-

Razor

-

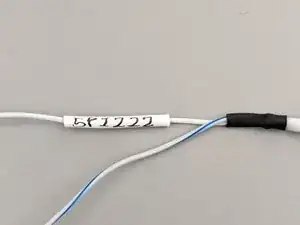

Fine tip sharpie, or label printer for wires

-

Heat gun

-

-

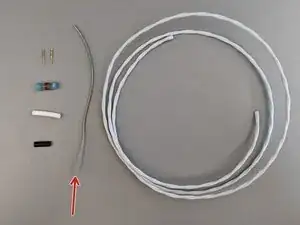

-

Interior wires- where the signal is passed through

-

Outer layer of insulation

-

Shielding- a braid inside the wire over the interior wires. This protects the signal from interference or interfering with other signals. The shielding is terminated to a ground

-

-

-

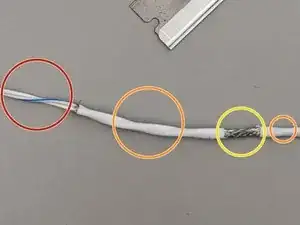

Remove shielding to expose wires

-

Option 1: unbraid shield and the cut away from wire

-

Option 2: carefully cut shield away without nicking the interior wires

-

-

-

Cut a 0.25" long section from outer layer of the wire about 2.5" from the end of the wire.

-

This accomplished with a razor. A new razor will cut more easily through the insulation but can also cut through the shielding. A dull razor is harder to cut with but also more forgiving to mistakes.

-

If the shielding is cut through and the interior wires nicked there is a high potential for a short to ground and that section of wire must be cut off and the wire must be restarted.

-

-

-

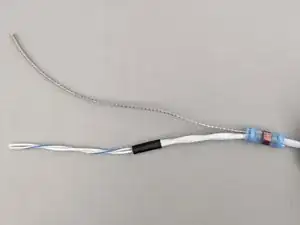

Insert the environmental splice over the cut shielding block and insert the shield braid into it. The solder ring must go over both the exposed shield and the braid.

-

Insert a piece of heat shrink over the end of the wire where the shield and outer insulation is cut. This will protect the end of the wire

-

Heat the splice and heat-shrink with a heat gun. Ensure the solder flows in the splice soldering the braid to the shield.

-

-

-

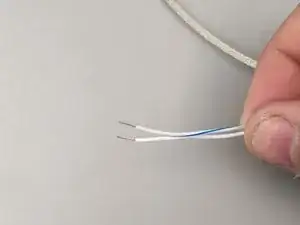

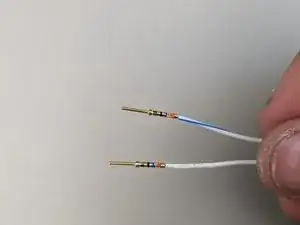

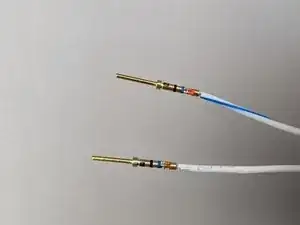

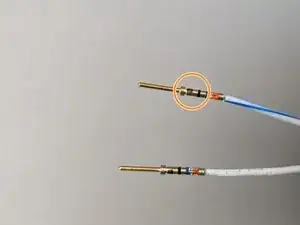

The wire strip length should by just barely longer than the barrel (where the wire goes) of the crimped contact

-

First picture shows a correct termination

-

Second picture shows to long of strip on wire

-

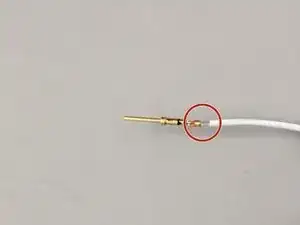

To make sure the wire is stripped long enough the conductor strands should be visible in the witness hole circled in the third picture

-

-

-

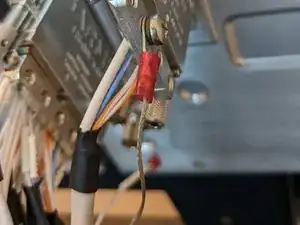

Crimp ring terminal to shield braid

-

Install ring terminal to designated grounding location. Often the connector back-shell.

-

This step is done last after all wires for a connector are installed and back-shell is assembled on connector. Sometimes a separate ground lug needs to be installed onto the back-shell.

-