Introduction

This is a guide to rewire a broken sensor cable on an MBH Fitness Water Rowing Machine.

The plastic connector found on rowing machines that connects the rowing sensor on the water reservoir with the LCD screen can be easily broken. This prevents the LCD screen from showing the rowing information while you work out. Thankfully, rewiring the sensor cable to restore that connection can be done at home.

In this guide, you will cut, strip, and crimp the wires of the sensor cables. Then you will seal with heat shrink tubing the wires to create two new sensor cable connections. These two connections will allow the LCD screen on your MBH Fitness Water Rowing Machine to read the rowing sensor again.

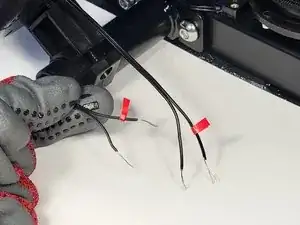

When determining the correct plastic connector orientation in Step 1, the metal pieces seen inside the connector pieces need to be on the same side. The metal pieces will touch if the connector were to be put together.

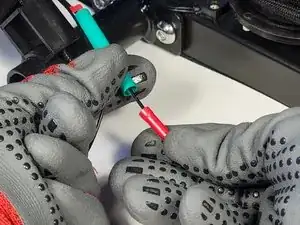

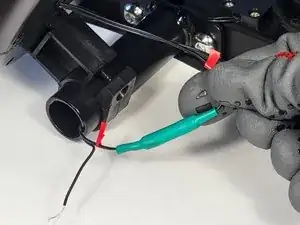

Before beginning, choose a heat shrink tube from the assortment that can fit over the RED (22-18 AWG) butt splice crimp terminal. This will prevent any issues when you do Step 14.

Please read the following caution statements:

Caution: In this guide, you will be working with a wire cutting tool. This tool can cause wire pieces to fly towards your eyes. Please wear safety goggles to protect your eyes.

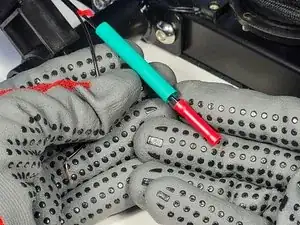

Caution: The ends of the cut wires can be sharp. Please wear work gloves to protect your hands from cuts.

Caution: In this guide, you will be using a hair dryer or heat gun. The hot air from these tools can cause burns.

Tools

-

-

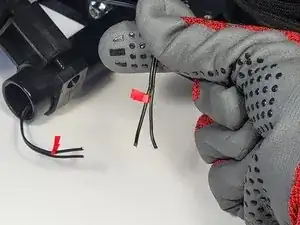

In the correct orientation, mark the wires that are opposite to each other with colored tape.

-

-

-

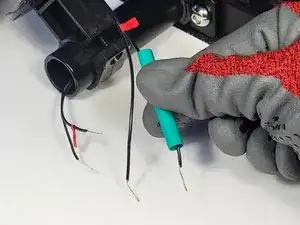

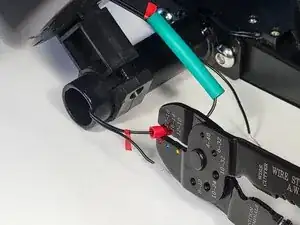

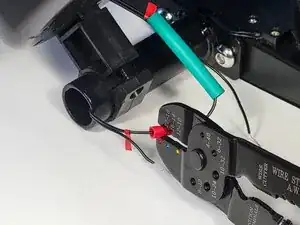

Cut the sensor cable with the wire cutting tool between the plastic connector and the colored tape.

-

-

-

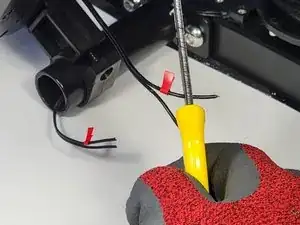

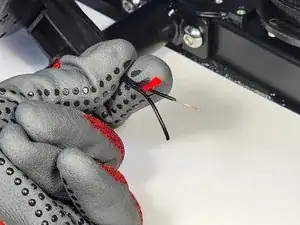

Place one of the four wires into the 20-22 AWG notch in the wire stripping tool, about 1/4 inch from the end of the wire.

-

-

-

-

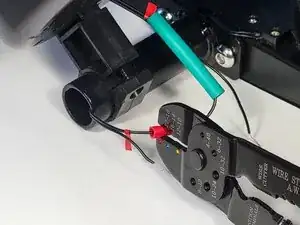

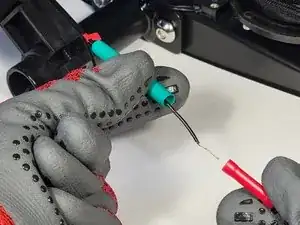

Place the 22-18 AWG notch of the wire crimping tool on one of end of the terminal.

-

Crimp the end of the terminal to secure the wire.

-

-

-

Cover the crimping terminal completely with the heat shrink tube.

-

Blow HOT air from the blow dryer or heat gun onto the heat shrink tubing, moving side to side, until it shrinks to closely fit the crimping terminal and the wires.

-

The LCD screen on your MBH Fitness Water Rowing Machine should now read the rowing sensor again.

Enjoy rowing!