Introduction

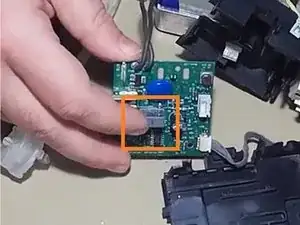

This issue should solve issues with lights not staying on or very dim.

There is an excellent video on YouTube here.

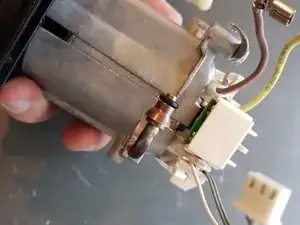

Here are the part details for the C1 capacitor on the PCB:

DigiKey Part Number: 399-5862-ND

Manufacturer Product Number: R463F310000M1M

Description: CAP FILM 0.1UF 20% 630VDC RADIAL

Tools

Parts

-

-

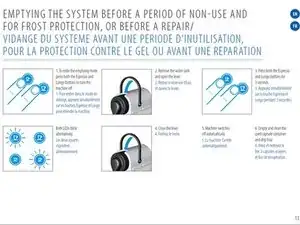

Remove all water from the system. (From the Nespresso manual.)

-

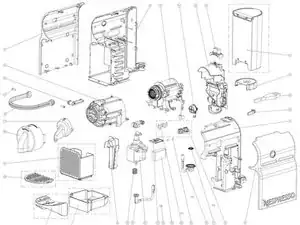

image 2: exploded view of the machine. Source: buyspares.com

-

-

-

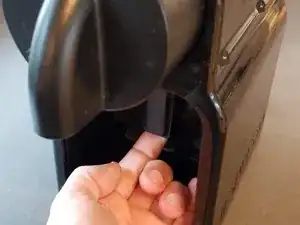

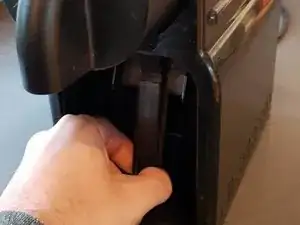

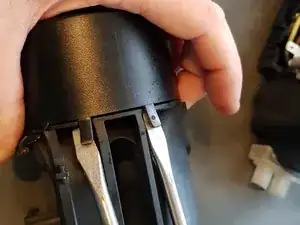

Pull straight forward with a fair amount of force.

-

Once you hear a click, pull the part straight down. This should go easilly.

-

-

-

Close the cup-holder firmly.

-

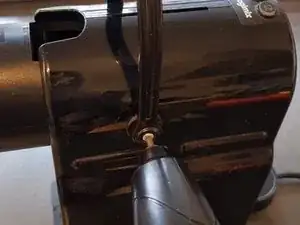

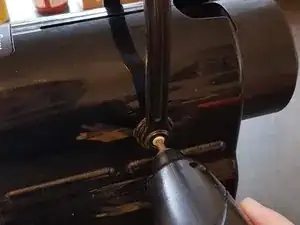

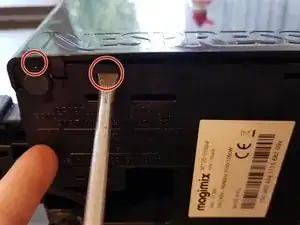

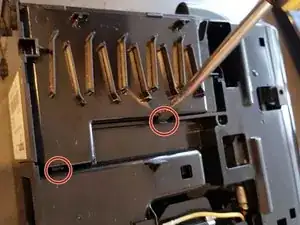

Photos 2 and 3, push the screwdriver in and wiggle a bit to undo the clips. There's a total of 4 clips.

-

-

-

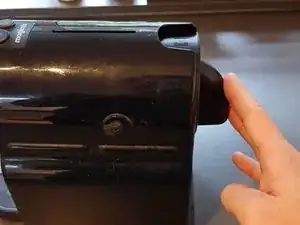

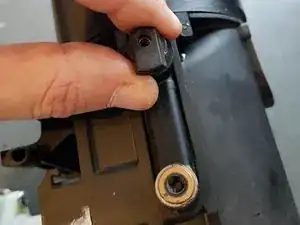

Make sure the notch lines up.

-

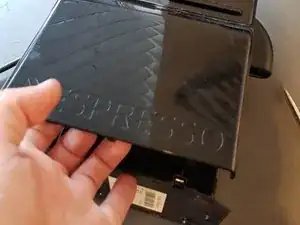

Pull the cover away. Once there's a little room, move your fingers up a bit and pull on the sides.

-

-

-

Unplug the device first! Remove ground, live and neutral wires.

-

Remove the whole wire from its slot.

-

-

-

Photo 1: Using leverage, pull up.

-

Photo 2: unclip the two clips on the inside of the cover.

-

Photo 3: turn over and lift the cover off.

-

-

-

Mark one of the black leads for proper reinstallation.

-

Remove the yellow and brown wire.

-

And the white connector.

-

-

-

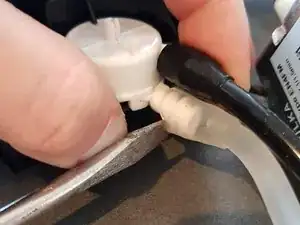

These clips are tricky to remove. The plastic rectangles housing the wire clips are part of the U-pipe. Bear this in mind when detaching the U-pipe from the two other (pump and boiler) pipes - which have cone shaped flanges; easy to push U-pipe faces onto, hard to detach.

-

Using the perspective of Photo1 for reference, for ease of working, ensure the background is down towards the floor, and ensure the metal pipe is braced, directly or via the boiler resting on a non-slip surface like a rubber mat or carpeted floor. Set-up the equivalent if working from the pump end of the U-pipe.

-

Push a 2.5mm thick pointed tool (rod or flat) into the wire loop that emerges from the centre-bottom of the plastic face. Do not make the loop emerge farther, but you can widen it <1mm with a suitable width screwdriver.

-

Left and right shoulders of the wire clip are to be pulled apart as far as the plastic face will allow. Start by inserting (and leaving in place) similar 2.5mm-3.5mm thick pointed/tapered tools between the outside edge of the plastic face and the exposed wire ends. Insert near each shoulder.

-

With the wire clip being held apart in three places, check that the wire in the centre of the plastic face is not still hugging the pipe but is just proud of the rim of the cone-flange. Another pointed tool may be needed to manipulate the rest of the wire over the edge of the cone-flange.

-

With the perspective of photo1 (or equivalent view from the pump), use a finger either side of the pipe to push the plastic face away from the boiler or away from the pump (towards the floor if positioned as advised earlier). The plastic face may need rocking during this process to manipulate any remaining wire over the last sub-mm of flange.

-

The joint should disconnect gracefully. If the joint does not disconnect, examine the centre hole of the plastic face again, checking where the wire is fouling the cone-flange. Reposition the three other pointed tools -previously left in place holding the wire apart- as necessary.

-

The 'O' ring each end of the plastic U-pipe will be easily accessible once the joint is apart. The inner diameter is approx 3mm. Outer diameter is approx 5mm ('O' ring is 1mm thick).

-

-

-

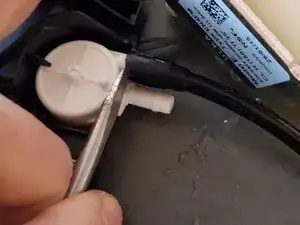

Photo 1 and 2, note the tapered edges, these hold the wire clip in place. Reinstallation is simple, just push the on again.

-

This was as far as I was able to go. In my case the part shown on the right in photo 3 was leaking in between the metal and plastic. Sadly it couldn't be disassembled any further.

-

-

-

Assembly is the reverse of disassembly. The next steps are some points of note.

-

Photo 1: reverse of step 11: The easiest way to reassemble the side is to lay it flat and lower the inner body onto the side.

-

Photo 2: reverse of step 11: Make sure the black line goes over the white one.

-

Fit the rubber collar back over the pump.

-

-

-

Photo 1: Don't forget this cover.

-

Photo 2: reverse of step 10: make sure the clips line up with the slots.

-

To reassemble your device, follow these instructions in reverse order.

cuando pulso los botones,se encienden los dos haciendo pausas cada tres encendidos ,y no paran que puede ser el motivo ??, gracias

moy5099 -

Prueba esto: Apague la máquina, mantenga pulsado el botón derecho (vaso grande) hasta que el botón izquierdo parpadee 3 veces, listo. Si esto no funciona: Apague, desenchufe, espere 1min, enchufe y continúe como arriba.

Si tienes mala suerte, esta es la causa: Nespresso CitiZ Capacitors Replacement

VauWeh -

Nello spaccato manca la parte che sta a contatto con le capsule e la leggenda con i numeri di riferimento dei pezzi.

Riccardo Ricci -