Introduction

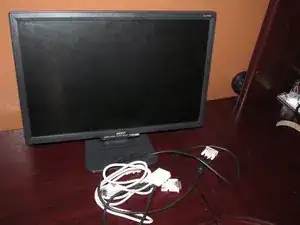

If your AL2216W is having problems, it is likely due to bad capacitors. Here are some common symptoms of bad capacitors:

Note: While some issues may be corrected with a partial repair, this is NOT RECOMMENDED. One bad capacitor usually means the rest will fail!

- Power issues (Present issue)

- Excessive transformer/inverter hum (Present)

- Backlight problems

- Auto adjust problems (VGA) (Present)

- Random power issues are only resolved through a full power cycle (unplugging the monitor)

- Video issues (Ex: Unstable image, video instability)

Original capacitor values (For Delta 00A power supply)

NOTE: I based the capacitor list on my monitor's specific power supply (Delta 00A). UNLESS YOU HAVE THE SAME PART IN YOUR MONITOR, YOU MUST VERIFY WHAT YOURS NEEDS TO AVOID COMPATIBILITY ISSUES BY TAKING THE MONITOR APART TO IDENTIFY WHAT CAPACITORS ARE USED. However in many cases the stock part is likely NLA or hard to find a matching replacement for, especially as these monitors age. As such it is very likely you will need to use different capacitors that either have a higher voltage or uF rating and swap all of the original capacitors that remain that match the old part, even if they work as doing this will likely cause the remaining original capacitors to fail sooner.

IMPORTANT: when swapping capacitors, stay as close to the original as you can. It’s okay to install a 35v 1000uf part in place of a 25v 1000uf part (or a 25v 2000uf replacement) but grossly exceeding the value of the stock part does not offer any benefits.

Part availability caution: While I did my best throughout this guide's life to keep up with part phaseouts (and "obsolete in practice" parts) by mitigating this issue with similar parts in voltage or uF, I cannot continuously monitor the market. You may need to make additional substitutions!

- 25V 1000uF (x2)

- 10V 1000uF (x1)

- 25V 220uF (x2)

- 16V 2200uF (x1, Found on early power supplies and is used to drive the inverter transformer. Not used on most power supply revisions as it was later removed)

Tools

Parts

-

-

Remove the 4 screws from the monitor stand with a Philips #1 screwdriver. Remove the bottom screws first.

-

-

-

Sort this screw separately, as it is unique.

-

Remove 4 fine threaded screws from the back of the monitor with a Phillips #0 screwdriver. All of these screws are the same.

-

-

-

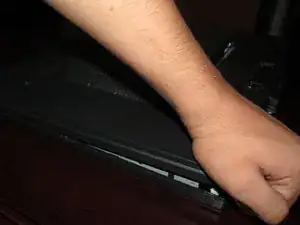

Open the monitor at the bottom of the monitor by releasing the four tabs with a flathead screwdriver or a Jimmy and plastic pry tool. If force is needed, the best way to do this is to put electrical tape on a flathead screwdriver and split the panels.

-

-

-

With the monitor unclipped on the bottom, pull the sides of the monitor up. Do this slowly to avoid cracking the LCD.

-

-

-

With the back of the monitor off, remove the 2 screws on the IEC power connector using a Phillips #0 screwdriver.

-

-

-

Remove the 4 screw pins for the video cables from the monitor. Use a 5mm Nut bit/driver to remove the screw pins from the power supply shield.

-

-

-

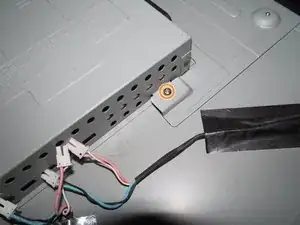

Remove the 2 lower screws that hold the power supply shield to the monitor with a Phillips #0 screwdriver.

-

-

-

On the right side of the monitor, remove the remaining Phillips #0 screws holding the board shield in place.

-

Lift the lower plate up while removing the power supply shield to remove it from the monitor. Once this is done, you will have access to the power supply.

-

Removing the lower shield (Optional): To remove the lower shield, release the black tabs holding it in place, and lift up. Do this for all the tabs holding it in place.

-

-

-

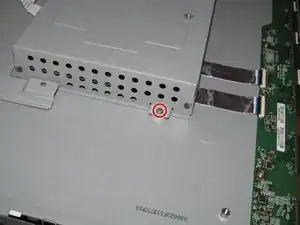

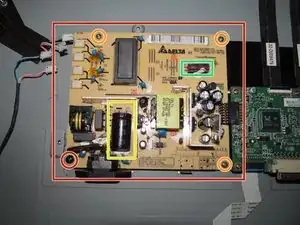

With the power supply shield removed from the monitor, identify the power supply. Take note of the printed values, including the inverter cap (if present).

-

Remove the 4 Phillips #1 screws from the power supply. Once this is done, lift up the power supply at a slight angle to clear the chassis. Do not lift too much or the connector may be damaged!

-

This capacitor is only found on older power supplies. Replacement is optional, but recommended.

-

-

-

If you are unsure of the position of the capacitors, mark the polarity with a permanent marker. If the capacitors are incorrectly installed, they will explode when power is applied.

-

-

-

Move to a workspace with ventilation or use a fume extractor. Once in an appropriate workspace, desolder the old capacitors. Heat up each leg and remove it.

-

After removing the capacitors, clean up the old solder with a desoldering braid. Lift it with the iron when removing it.

-

-

-

Install the new capacitors. Check the polarity and bend the leads so they do not come loose during installation.

-

-

-

Once the polarity is verified, solder the capacitors in. After installation, cut off any excess lead.

-

-

-

After verifying there are no cold solder joints, clean the board with 91%+ Isopropyl alcohol, or denatured alcohol.

-

To reassemble your device, follow these instructions in reverse order.

28 comments

I did not replace the large capacitor on the Acer monitor yet. All other caps have been replaced. I may have to replace the FSPO55- ZP102A as it has a hot spot beside it. I don't know if the part number is right? Do know where I can buy it. Tom B

These older CCFL panels usually burn on the PCB by the inverter coil and main transformer (the Delta branded part, in this case). The LED monitors limit the failure points to the transformer.

It sounds like your PCB got burned from the heat by the transformer or the inverter coil. This is very common and the boards are designed to take it. However, if you are concerned you should buy a new power supply board altogether if that makes you more comfortable.

Nick -

In step 12, replacing the capacitors with ones with a different capacitance rating instead of using a capacitor rated for higher voltage makes no sense to me electrically. The capacitance rating is the important part, if you use a capacator rated for say 35 volts when the original is rated for 10 makes no difference whatsoever. the rating just means MAX voltage.

The big one on the AC side.

Nick -

It’s okay to use the matched and upgraded caps at the same time. The ones I upgraded were hard to find since they’re more or less obsolete.

Nick -

Ok thanks! reason why is I got all my replacements scrapping dead Power supplies. so I managed to get some and some others

Aiden -

That’s a way to get extra groundplane with minimal cost. By design, it gets covered in solder during assembly. I wouldn’t leave solder on those.

Nick -

also one more thing. which capacitors do the upgraded ones replace?

Aiden -

Yeah. It’s a bad idea to bridge it. The places the upgraded caps go are listed in the part descriptions as a note if it was replaced.

Nick -

OK. I didn’t expect to find the monitor I needed to replace on ifixit out of tons of others that are not. thanks for making the guide!

Aiden -

Most of the monitors people usually buy are low end and are rarely worth repairing or the owner is too lazy to bother because of how cheap a good one is today. I only ever see good monitors like Dell Ultrasharps in use by businesses.

On one hand it’s a waste but if I can get it and fix it for relatively little money I’ll try.

Nick -

The capacitor by the coil. Some revisions don’t have it.

Nick -

the one in step 12?

Aiden -

The one with the red box around it.

Nick -

@captainsnowball And I figured out what the issue may have been almost 4 years later :-(. I assumed the Delta 00A supply was the common unit and common sense would dictate the information on the caps I have is specific to the 00A part, but that wasn’t the case.

It’s been fixed for a while, but the issue has been ongoing for a long time because it’s been patched to help rather then properly fixed. I’m going to keep it for cases like yours where you need a starting point, but it had to be clarified. The monitor really needs to come apart to be sure, so I may remove it as it isn’t definite and may vary.

Nick -