Introduction

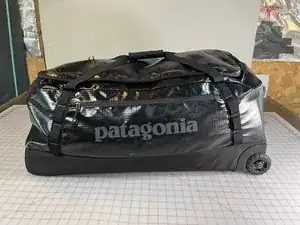

Wheels on roller luggage can wear down over time or even detach completely. When this happens, the best solution is a full wheel replacement.

This guide will demonstrate how to assess wheel damage and replace the wheels and axles of a Patagonia Black Hole® Wheeled Duffel.

Replacement parts are currently unavailable. To get your luggage fixed, take it in to a local Patagonia retail store for repair evaluation or send it in to Patagonia through their mail-in repair service.

Related Tutorials

Tools

Parts

-

-

Starting with an empty duffel, open the main zipper compartment.

-

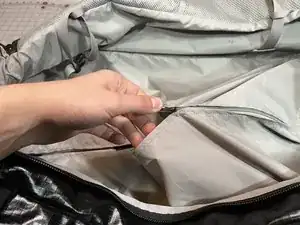

Locate the zipper in the liner and open. This will expose the inside of the plastic wheel housing.

-

If the wheel and axle are missing, a nut and washer may be loose inside this liner compartment. Try to locate the washer and nut to reuse.

-

-

-

If the damaged wheel and axle are still attached, locate the axle nut inside the liner compartment and hold it in place with the adjustable wrench.

-

From the outside, turn the axle using the 4mm Allen wrench to free the wheel and axle from the plastic wheel housing. Save the washer and nut to reuse.

-

Test the other wheel for functionality and remove if it is broken.

-

-

-

Assess both wheels on the luggage:

-

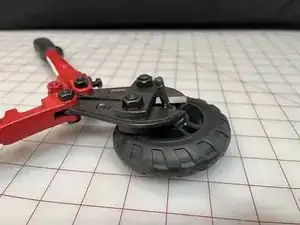

Damaged Tread – If the wheel has a worn rubber tread or a flat spot (reference image #2), the wheel must be replaced, skip to Step 5.

-

Damaged Axle – If the original wheel is in working shape, but the axle is bent (reference image #3), continue to Step 4.

-

Missing Wheel – If both the wheel and axle are missing, skip to Step 5.

-

Responsibly discard any unusable pieces.

-

-

-

If the original wheel is in working shape, but the axle is bent, you can often free the wheel by cutting the axle off.

-

Using bolt cutters, cut the axle as close to wheel as possible.

-

If the cut axle remains stuck inside the wheel, elevate the wheel with a sturdy surface, and tap the cut end of the axle using a flat head screwdriver and a hammer until the axle is driven out.

-

-

-

There is often excess foam and lining fabric blocking access to the back of the plastic housing.

-

It is okay to cut away this excess using an X-Acto blade.

-

-

-

Place a new or salvaged wheel onto a new axle and insert the axle into the plastic wheel housing.

-

Inside the plastic wheel housing, place a washer and a nut onto the axle and finger-turn until attached.

-

Then use the adjustable wrench to keep the nut in-place and tighten the axle from the outside using the 4mm Allen wrench.

-

-

-

Check the liner compartment to make sure no tools have been left behind.

-

Close the zipper to the liner compartment.

-

One comment

Thanks! Saved me a few emails and phone calls✨